Search by operation

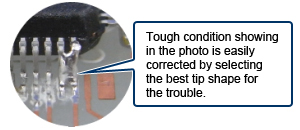

Correcting Bridging

The following shapes are recommended. Please select the best shape for the solder amount. Please operate with clean tip.

* Click icon and jump to each tip shape details.

The following causes are assumed:

- Soldering feed amount is too large.

- Soldering feed amount is too large.

- Iron movement speed is too fast.

- The tip is oxidized.

Pb (lead) free soldering tends to be bridging due to its characteristic of clingness. While paying attention to the above 3 points, drag the tip slowly as if absorbing the solder of the bridged-section or placing it on the tip.

* In the soldering industry, solder condition is called “non-clingness” when solder cuts easily and come off the work. Pb free solder tends to cling and causes some problems such as bridging due to its high viscosity.

How is bridging prevented?

Changing tip shapes can prevent it.

- In case of drag soldering, Shape BCM/CM having the hollow with its surface is recommended.

- In case of soldering at narrow pitches, the soldering tips with fine tip end are recommended.

Refer to “Soldering at the narrow pitches”.

Use Shape BCM/CM

This shape has the hollow section to its cut face, providing high solder retention capability. It offers other recommended usages.

| 1. Clean solder left in the hollow section by a cleaning sponge, etc. A small amount of solder may be left in the hollow section. 2. Put the tip on the bridge section and drag it.

|

Use Shape J

This shape differs from Shape B and I by bending the tip end and is capable of soldering by applying the tip in 2 ways: face and point. It offers other recommended usages.

| If the bridge amount is small Stand the tip on end and drag the tip slowly. | ||

| If the bridge amount is large

|

Use Shape K

This type has a shape like a knife and is capable of soldering by applying the tip in 3 ways: line, face and point. It is used for soldering at narrow pitches, correction of bridging and drag soldering.

| If the bridge amount is small Stand the blade on edge and drag the tip slowly. * Do not stand the blade up at too steep angle. Doing so will damage the P.W.B. |

| If the bridge amount is large Lay the blade down and drag the tip slowly. |

Use Shape H

This shape differs from Shape J by cutting the tip end. It offers other recommended usages.

| If the bridge amount is small Lay down the pad section and drag the tip slowly. |

| If the bridge amount is large Lay down the pad section and drag the tip slowly. |