Search by operation

Drag soldering

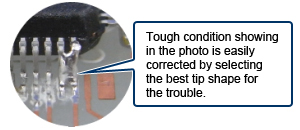

The following shapes are recommended. Apply flux to leads and land pads before soldering. It prevents the troubles such as solder bridge and insufficient solder.

* Click icon and jump to each tip shape details.

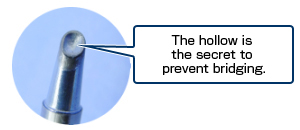

Shape BCM/CM having the hollow with its surface is recommended. It is also suitable for correcting bridging. |  |

The various shapes are available for correcting bridging. For further details, see the following page which also introduces the causes of bridging. |  |

Use Shape BCM/CM

This shape has the hollow section to its cut face, providing high solder retention capability. It offers other recommended usages.

| Feed solder on a hollow section and drag the tip along slowly. |

Use Shape BC/C

This type has a shape like a cone or column cut at a slant, which allows users to select the cut surface size depending on the workpiece. It is used for drag soldering and pre-tinning of lead wires.

| Put the cut surface to the leads and drag it slowly. |

|

Use Shape B

This shape is all-round type which can be used from any direction and is easy to hold at any position. It offers other recommended usages.

| Put the tip end to the leads and drag it slowly. Check the right timing to feed solder. |

Use Shape D

This type has a shape like a flat-blade screwdriver and is capable of soldering by applying the tip in 2 ways: line and face. It is available for any works.

| Put the tip end to the leads and drag it slowly.

|

Use Shape J

This shape differs from Shape B and I by bending the tip end and is capable of soldering by applying the tip in 2 ways: face and point. It offers other recommended usages.

| Lay down the end pad section and drag the tip slowly. Check the right timing to feed solder. |

Use Shape K

This type has a shape like a knife and is capable of soldering by applying the tip in 3 ways: line, face and point. It is used for soldering at narrow pitches, correction of bridging and drag soldering.

| PTH Put the tip to the leads while laying down the entire blade and drag it slowly. * Lay the blade down to thoroughly transfer sufficient heat to the pattern. |

| QFP Put the tip to the leads while laying down the entire blade and drag it slowly. * Lay the blade down to thoroughly transfer sufficient heat to the pattern. |

Use Shape H

This shape differs from Shape J by cutting the tip end. It offers other recommended usages.

| Put the pad section to the leads and drag the tip along slowly. |